Application

Ion Exchange for Thermal Power Plants

Application of ion exchange resin to softening hard water in power plant

Application

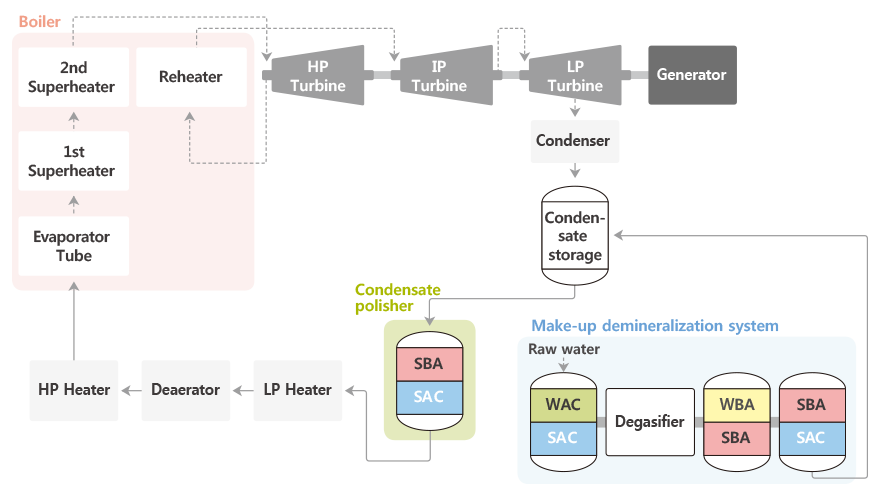

Ion exchange resins for thermal power plant are classified by applications: Make-up system, condensate polishing, etc. Various combinations of demineralization are adaptable for Make-up system for the power plant. For condensate polishing plant (CPP), premium grade IERs are required with high operating capacity, high operating temperature, and mechanical and chemical stability.

COMCESS ion exchange resins record the various supply references to domestic and foreign thermal power plants hence contributing to the competitive power supply for customers, with stable quality control and on-time delivery of resins.

COMCESS ion exchange resins record the various supply references to domestic and foreign thermal power plants hence contributing to the competitive power supply for customers, with stable quality control and on-time delivery of resins.

Typical power plant steam surbine loop and IER selection

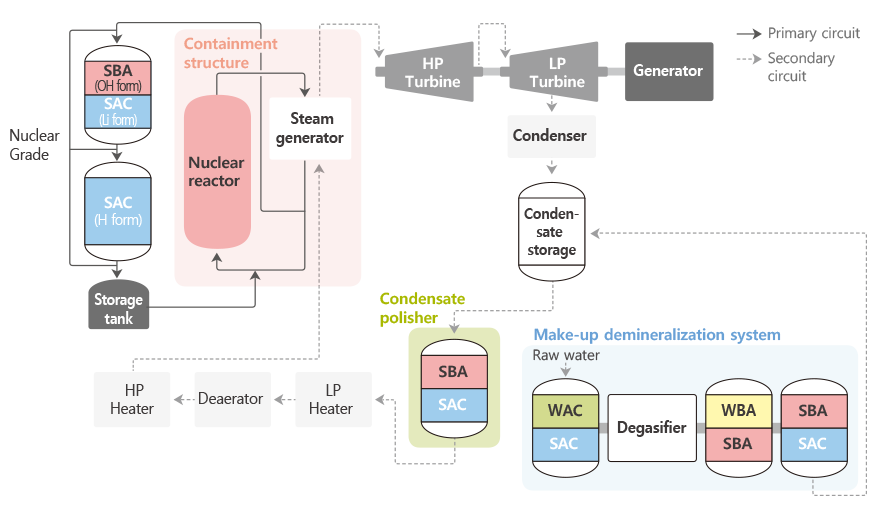

Nuclear Power Plants:

ion exchange resins for nuclear power plant are classified by applications: Make-up system, condensate polishing and primary circuit for the nuclear power plant. For the primary circuit in the nuclear power plant, IERs are exposed to radiation. Use of high crosslinkage IERs with low impurities, high mechanical and chemical stability is highly recommended.

COMCESS Ion exchange resins record the various supply references to domestic and foreign nuclear power plants hence contributing to the competitive power supply for customers, with stable quality control and on-time delivery of resins.

Pressurized water reactor type nuclear power plant steam turbine loop and IER selection

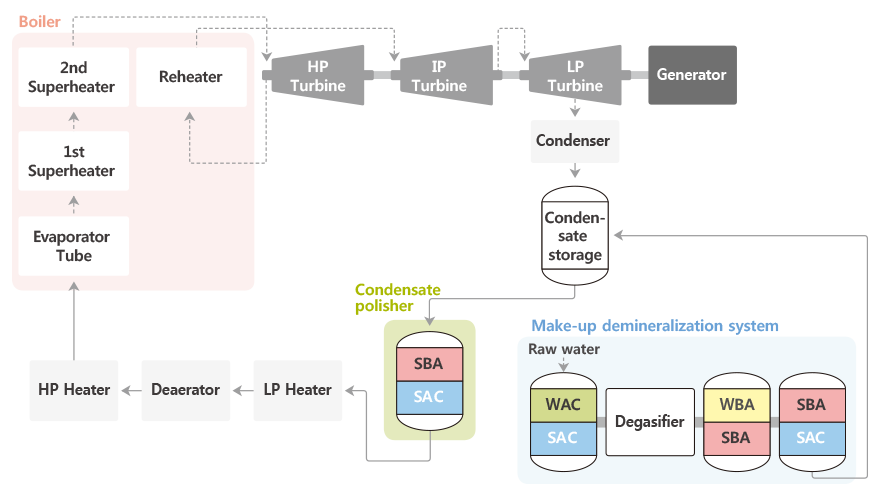

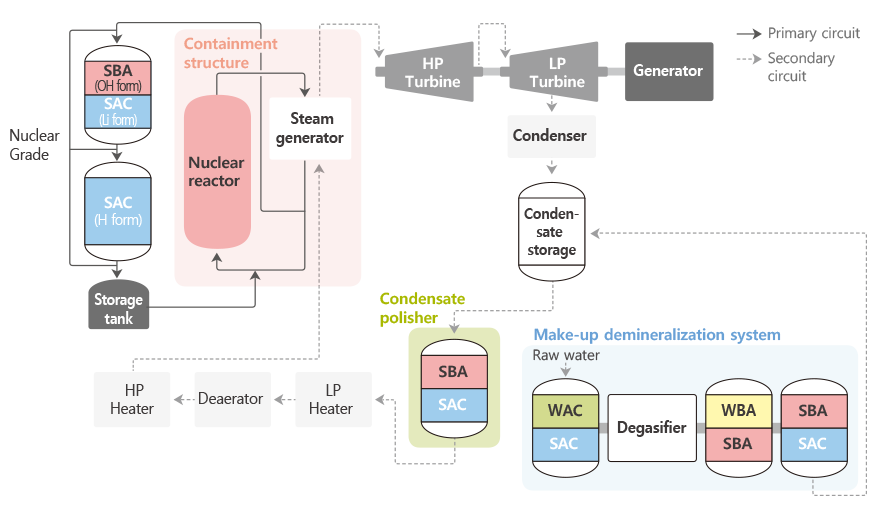

Nuclear Power Plants:

ion exchange resins for nuclear power plant are classified by applications: Make-up system, condensate polishing and primary circuit for the nuclear power plant. For the primary circuit in the nuclear power plant, IERs are exposed to radiation. Use of high crosslinkage IERs with low impurities, high mechanical and chemical stability is highly recommended.

COMCESS Ion exchange resins record the various supply references to domestic and foreign nuclear power plants hence contributing to the competitive power supply for customers, with stable quality control and on-time delivery of resins.

Pressurized water reactor type nuclear power plant steam turbine loop and IER selection

Related Products

-

.png) Anionic Polyacrylamide ResinPurity : 99.9%Color : WhiteMelting Point : >150°℃

Anionic Polyacrylamide ResinPurity : 99.9%Color : WhiteMelting Point : >150°℃ -

201×2 Strong Base Anion Exchange resin(Gel Type)Appearance: Light yellow to gold yellow transparency sphericity particles.The degree of crosslinking : 2%.Ionic form: Cl-

201×2 Strong Base Anion Exchange resin(Gel Type)Appearance: Light yellow to gold yellow transparency sphericity particles.The degree of crosslinking : 2%.Ionic form: Cl- -

C010FG Food Grade Drug Purification Exchange ResinAppearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 10%.Ionic form:Na+

C010FG Food Grade Drug Purification Exchange ResinAppearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 10%.Ionic form:Na+