Application

Application of Ion Exchange Resins in Biodiesel Production?

These molecules may be collected inside or outside the pores, which may hinder the evaluation of active sites by FFAs and methanol. Compared with gel resin, Comcess DXC ion exchange resin has wider pores and active surface area, which is more suitable for the production of biodiesel.

Application

Biodiesel is an important green alternative fuel in the global transportation sector, which is environmentally friendly and renewable. Biofuels extracted from renewable natural energy sources are a viable alternative to fossil fuels. Biodiesel based on renewable animal and plant fats can be directly used in internal combustion engines without the need for engine modification.

Biodiesel is typically produced by extracting methyl esters from bio oils through ester exchange reactions. Rapeseed oil, soybean oil, corn oil, waste animal fat, and waste edible oil can all be used as raw materials for biodiesel. These raw materials include a large amount of free fatty acids (FFAs), and in order to make biodiesel economically acceptable, esterification reactions should be carried out to reduce the amount of free fatty acids.

During the laboratory process, strong acid cationic resin was used to pretreat 13% FFA in crude palm kernel oil. For Cationic Resins, firstly, triglycerides are adsorbed onto the resin, followed by protonation of ester carbonyl groups and nucleophilic attack of alcohols, all of which contribute to the generation of diglycerides, monotriglycerides, and FFA. However, the first step in using Anionic Resins for ester exchange is the adsorption of alcohols on resin catalysts, resulting in the production of alcohols and protonated catalysts. Then the alcohol salt reacts with triglycerides to form alkyl esters and corresponding triglyceride anions.

Under moderate reaction conditions, the catalytic activity of ion exchange resin is sufficiently high. Therefore, ion exchange resins are suitable for industrial processes of producing biodiesel together with high FFA content raw materials. The active area of ion exchange resins can vary according to their pore structure. In the production of biodiesel, the raw materials are usually composed of macromolecules such as glycerides. These molecules may be collected inside or outside the pores, which may hinder the evaluation of active sites by FFAs and methanol. Compared with gel resin, Comcess DXC ion exchange resin has wider pores and active surface area, which is more suitable for the production of biodiesel.

Biodiesel is typically produced by extracting methyl esters from bio oils through ester exchange reactions. Rapeseed oil, soybean oil, corn oil, waste animal fat, and waste edible oil can all be used as raw materials for biodiesel. These raw materials include a large amount of free fatty acids (FFAs), and in order to make biodiesel economically acceptable, esterification reactions should be carried out to reduce the amount of free fatty acids.

During the laboratory process, strong acid cationic resin was used to pretreat 13% FFA in crude palm kernel oil. For Cationic Resins, firstly, triglycerides are adsorbed onto the resin, followed by protonation of ester carbonyl groups and nucleophilic attack of alcohols, all of which contribute to the generation of diglycerides, monotriglycerides, and FFA. However, the first step in using Anionic Resins for ester exchange is the adsorption of alcohols on resin catalysts, resulting in the production of alcohols and protonated catalysts. Then the alcohol salt reacts with triglycerides to form alkyl esters and corresponding triglyceride anions.

Under moderate reaction conditions, the catalytic activity of ion exchange resin is sufficiently high. Therefore, ion exchange resins are suitable for industrial processes of producing biodiesel together with high FFA content raw materials. The active area of ion exchange resins can vary according to their pore structure. In the production of biodiesel, the raw materials are usually composed of macromolecules such as glycerides. These molecules may be collected inside or outside the pores, which may hinder the evaluation of active sites by FFAs and methanol. Compared with gel resin, Comcess DXC ion exchange resin has wider pores and active surface area, which is more suitable for the production of biodiesel.

Related Products

-

Arsenic Removing Chelating Resin To Extract Heavy Metals Removal Arsenic Removal Nitrate Ion Exchange ResinAppearance: Red brown to brown beadsIonic form:[R-FeO (OH)]+Volume complete exchange capacity(mmol/ml):≥2.0

Arsenic Removing Chelating Resin To Extract Heavy Metals Removal Arsenic Removal Nitrate Ion Exchange ResinAppearance: Red brown to brown beadsIonic form:[R-FeO (OH)]+Volume complete exchange capacity(mmol/ml):≥2.0 -

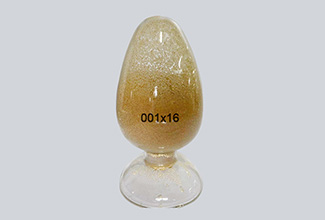

001x16 Strong Acid Cation Exchange ResinAppearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 16%.Ionic form:Na+

001x16 Strong Acid Cation Exchange ResinAppearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 16%.Ionic form:Na+ -

001X8 water softener ion exchange ResinIonic form:Na+Appearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 8%.

001X8 water softener ion exchange ResinIonic form:Na+Appearance: Claybank to tan transparent spherical particle.The degree of crosslinking : 8%.